What are the Product Features of Capacitor Film?

I. Introduction

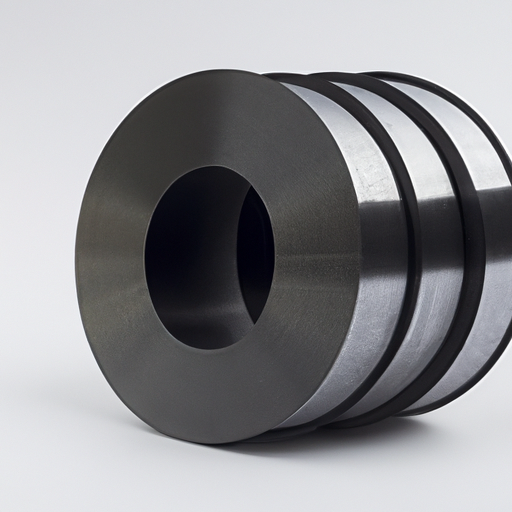

A. Definition of Capacitor Film

Capacitor film, commonly referred to as film capacitors, is a type of capacitor that uses a thin plastic film as the dielectric material. These capacitors are widely used in various electronic applications due to their excellent electrical properties and reliability.

B. Importance of Capacitor Film in Electronics

In the realm of electronics, capacitors play a crucial role in energy storage, filtering, and signal processing. Film capacitors, in particular, are favored for their stability, low losses, and ability to operate over a wide range of temperatures and frequencies. Their unique characteristics make them suitable for applications ranging from consumer electronics to industrial machinery.

C. Purpose of the Document

This document aims to provide a comprehensive overview of the product features of capacitor film, exploring their composition, key characteristics, performance metrics, applications, and comparisons with other capacitor types.

II. Overview of Capacitor Film

A. What is a Capacitor?

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material, known as the dielectric. When voltage is applied, an electric field is created, allowing the capacitor to store energy.

B. Types of Capacitors

Capacitors come in various types, including ceramic, electrolytic, tantalum, and film capacitors. Each type has its own set of characteristics, making them suitable for different applications.

C. Role of Film Capacitors in the Capacitor Family

Film capacitors are a subset of capacitors that utilize a thin film as the dielectric. They are known for their stability, low loss, and high reliability, making them ideal for applications requiring precision and durability.

III. Composition and Structure of Capacitor Film

A. Materials Used in Film Capacitors

Film capacitors are made from various materials, each contributing to their unique properties:

1. **Polypropylene**: Known for its low dielectric loss and high insulation resistance, polypropylene is commonly used in high-frequency applications.

2. **Polyester**: This material offers good electrical properties and is often used in general-purpose applications.

3. **Polycarbonate**: With excellent thermal stability, polycarbonate is suitable for applications requiring high reliability.

4. **Other Materials**: Other materials, such as polyamide and fluoropolymer, may also be used depending on specific application requirements.

B. Construction of Film Capacitors

The construction of film capacitors involves several key components:

1. **Dielectric Layer**: The thin film that acts as the insulating layer between the conductive plates.

2. **Electrode Layers**: Typically made of metal, these layers are applied to both sides of the dielectric film to create the capacitor's plates.

3. **Encapsulation**: The entire assembly is often encapsulated in a protective material to enhance durability and environmental resistance.

IV. Key Product Features of Capacitor Film

A. Electrical Characteristics

1. **Capacitance Range**: Film capacitors are available in a wide range of capacitance values, typically from a few picofarads to several microfarads, making them versatile for various applications.

2. **Voltage Ratings**: They can handle voltage ratings from a few volts to several kilovolts, depending on the design and materials used.

3. **Tolerance Levels**: Film capacitors generally offer tight tolerance levels, often within ±5% to ±10%, ensuring precise performance in circuits.

B. Thermal Stability

1. **Operating Temperature Range**: Film capacitors can operate effectively over a broad temperature range, typically from -40°C to +85°C, with some specialized types rated for even higher temperatures.

2. **Thermal Aging**: They exhibit excellent thermal aging characteristics, maintaining their performance over time even under high-temperature conditions.

C. Dielectric Properties

1. **Dielectric Constant**: Film capacitors have a relatively high dielectric constant, which contributes to their capacitance values.

2. **Dissipation Factor**: They exhibit low dissipation factors, indicating minimal energy loss during operation.

3. **Insulation Resistance**: Film capacitors provide high insulation resistance, ensuring reliable performance and longevity.

D. Reliability and Longevity

1. **Lifespan and Endurance**: Film capacitors are known for their long lifespan, often exceeding 10,000 hours of continuous operation at rated voltage and temperature.

2. **Failure Modes**: They typically fail gracefully, meaning they are less likely to short-circuit compared to other capacitor types, enhancing overall circuit reliability.

E. Size and Form Factor

1. **Physical Dimensions**: Film capacitors come in various sizes, allowing for flexibility in design and application.

2. **Mounting Options**: They are available in different mounting styles, including through-hole and surface mount, catering to diverse circuit board designs.

F. Environmental Resistance

1. **Moisture Resistance**: Film capacitors are generally resistant to moisture, making them suitable for humid environments.

2. **Chemical Resistance**: They can withstand exposure to various chemicals, enhancing their durability in industrial applications.

3. **UV Stability**: Many film capacitors are designed to resist degradation from ultraviolet light, ensuring long-term performance in outdoor applications.

V. Performance Characteristics

A. Frequency Response

1. **Self-Resonant Frequency**: Film capacitors exhibit a self-resonant frequency, beyond which their impedance decreases significantly, making them suitable for high-frequency applications.

2. **Impedance Characteristics**: They maintain stable impedance across a wide frequency range, ensuring consistent performance in signal processing applications.

B. Ripple Current Handling

Film capacitors can handle significant ripple currents, making them ideal for power supply applications where fluctuating currents are common.

C. Voltage Coefficient

The voltage coefficient of film capacitors indicates how their capacitance changes with applied voltage. This characteristic is crucial for applications requiring stable capacitance under varying voltage conditions.

VI. Applications of Capacitor Film

A. Consumer Electronics

Film capacitors are widely used in consumer electronics, including televisions, audio systems, and home appliances, due to their reliability and performance.

B. Industrial Equipment

In industrial settings, film capacitors are employed in motor drives, power supplies, and control systems, where their durability and thermal stability are essential.

C. Automotive Applications

Film capacitors are increasingly used in automotive electronics, including power management systems and infotainment units, where reliability is critical.

D. Renewable Energy Systems

In renewable energy applications, such as solar inverters and wind turbines, film capacitors play a vital role in energy storage and conversion.

E. Audio Equipment

High-fidelity audio equipment often utilizes film capacitors for their low distortion and excellent frequency response, enhancing sound quality.

VII. Comparison with Other Capacitor Types

A. Film Capacitors vs. Ceramic Capacitors

While ceramic capacitors are compact and cost-effective, film capacitors offer better stability and lower losses, making them preferable for high-performance applications.

B. Film Capacitors vs. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values but have limitations in terms of voltage ratings and lifespan. Film capacitors, on the other hand, provide greater reliability and longevity.

C. Advantages and Disadvantages

Film capacitors excel in stability, reliability, and low losses, but they may be bulkier and more expensive than other types, such as ceramic or electrolytic capacitors.

VIII. Conclusion

A. Summary of Key Features

Capacitor film offers a unique combination of electrical characteristics, thermal stability, reliability, and environmental resistance, making them a preferred choice in various applications.

B. Future Trends in Capacitor Film Technology

As technology advances, the demand for smaller, more efficient capacitors will drive innovations in film capacitor design and materials, leading to enhanced performance and new applications.

C. Final Thoughts on the Importance of Capacitor Film in Modern Electronics

In an increasingly electronic world, capacitor film remains a cornerstone component, ensuring the reliability and efficiency of countless devices and systems. Understanding their features and applications is essential for engineers and designers aiming to create cutting-edge electronic solutions.

IX. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Applied Physics

B. Industry Reports

- Capacitor Market Analysis Reports

- Electronic Components Industry Trends

C. Manufacturer Specifications

- Datasheets from leading capacitor manufacturers

D. Online Resources

- Electronics tutorials and capacitor technology websites

This comprehensive overview of capacitor film highlights its essential features and applications, providing valuable insights for anyone interested in the field of electronics.