Market Policies for Aluminum Electrolytic Capacitors

I. Introduction

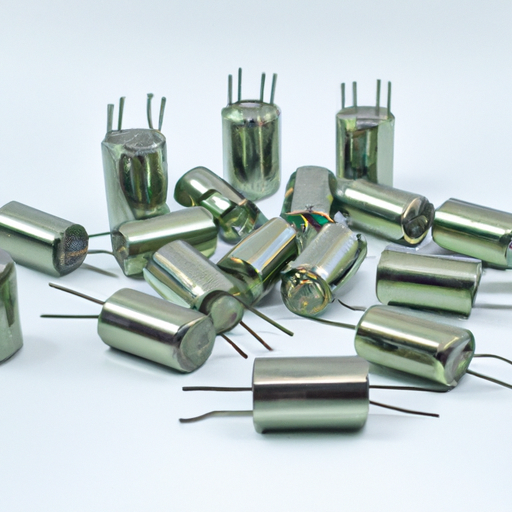

Aluminum electrolytic capacitors are essential components in modern electronic devices, known for their ability to store and release electrical energy efficiently. These capacitors are widely used in various applications, from consumer electronics to automotive systems, due to their high capacitance values and relatively low cost. As the demand for these components continues to grow, understanding the market policies that govern their production, distribution, and regulation becomes increasingly important. This blog post will explore the market policies for aluminum electrolytic capacitors, providing insights into the regulatory frameworks, trade policies, environmental considerations, and market strategies that shape this industry.

II. Market Overview

A. Global Market Landscape

The global market for aluminum electrolytic capacitors has witnessed significant growth over the past few years. Key players in this market include established manufacturers such as Nippon Chemi-Con, Panasonic, and Vishay Intertechnology, among others. These companies dominate the market due to their extensive product portfolios and strong distribution networks.

The market size for aluminum electrolytic capacitors is projected to grow at a compound annual growth rate (CAGR) of around 5% over the next few years, driven by increasing demand from various sectors. The rise of consumer electronics, automotive applications, and renewable energy systems are key factors contributing to this growth.

B. Applications of Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors find applications in several industries:

1. **Consumer Electronics**: These capacitors are commonly used in devices such as televisions, computers, and smartphones, where they help stabilize voltage and filter signals.

2. **Automotive Industry**: In vehicles, aluminum electrolytic capacitors are used in power supply circuits, audio systems, and electronic control units, playing a crucial role in enhancing performance and reliability.

3. **Industrial Applications**: Industries utilize these capacitors in machinery and equipment for energy storage and power factor correction, ensuring efficient operation.

4. **Renewable Energy Systems**: With the growing emphasis on sustainability, aluminum electrolytic capacitors are increasingly used in solar inverters and wind turbine systems, contributing to the efficiency of renewable energy technologies.

III. Regulatory Framework

A. International Standards and Certifications

The production and use of aluminum electrolytic capacitors are subject to various international standards and certifications to ensure safety, reliability, and environmental compliance. Key standards include:

1. **IEC (International Electrotechnical Commission)**: The IEC sets global standards for electrical and electronic devices, including capacitors, ensuring they meet safety and performance criteria.

2. **RoHS (Restriction of Hazardous Substances)**: This directive restricts the use of certain hazardous materials in electrical and electronic equipment, promoting safer manufacturing practices.

3. **REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals)**: REACH regulates chemical substances used in manufacturing, ensuring that companies assess and manage risks associated with chemicals.

B. Regional Regulations

Regulatory frameworks vary by region, impacting how aluminum electrolytic capacitors are produced and marketed:

1. **North America**: In the U.S. and Canada, regulations focus on safety standards and environmental compliance, with agencies like the Environmental Protection Agency (EPA) overseeing compliance.

2. **Europe**: The European Union has stringent regulations regarding environmental impact and product safety, including RoHS and REACH, which manufacturers must adhere to.

3. **Asia-Pacific**: Countries in this region are increasingly adopting international standards, with a focus on improving product quality and environmental sustainability.

C. Compliance and Testing Requirements

Manufacturers must comply with various testing requirements to ensure their products meet regulatory standards. This includes electrical testing, environmental testing, and safety assessments, which can be time-consuming and costly but are essential for market access.

IV. Trade Policies

A. Import and Export Regulations

Trade policies significantly impact the aluminum electrolytic capacitor market, particularly regarding import and export regulations:

1. **Tariffs and Duties**: Tariffs imposed on imported components can affect pricing and competitiveness. Manufacturers must navigate these tariffs to maintain profitability.

2. **Trade Agreements**: Free trade agreements can facilitate smoother trade between countries, reducing tariffs and promoting market access for manufacturers.

B. Impact of Global Trade Tensions

Recent global trade tensions, particularly between the U.S. and China, have created uncertainty in the market. Tariffs on electronic components can disrupt supply chains, leading to increased costs and potential shortages. Companies must adapt their strategies to mitigate these risks, such as diversifying suppliers and exploring alternative markets.

V. Environmental Policies

A. Sustainability Initiatives

As environmental concerns grow, the aluminum electrolytic capacitor industry is increasingly focusing on sustainability initiatives:

1. **Eco-Friendly Manufacturing Practices**: Manufacturers are adopting greener production methods, reducing waste and energy consumption during the manufacturing process.

2. **Recycling and Waste Management**: The industry is also exploring recycling options for aluminum electrolytic capacitors, promoting a circular economy and minimizing environmental impact.

B. Impact of Environmental Regulations on Production

Environmental regulations can influence production processes, requiring manufacturers to invest in cleaner technologies and practices. While this may increase initial costs, it can lead to long-term savings and improved brand reputation.

C. Corporate Social Responsibility (CSR) in the Industry

Many companies in the aluminum electrolytic capacitor market are embracing corporate social responsibility (CSR) initiatives, focusing on ethical practices, community engagement, and environmental stewardship. This commitment can enhance brand loyalty and attract environmentally conscious consumers.

VI. Market Strategies

A. Pricing Strategies

Pricing strategies play a crucial role in the competitiveness of aluminum electrolytic capacitors:

1. **Cost-Plus Pricing**: Manufacturers often use cost-plus pricing to ensure profitability while covering production costs.

2. **Competitive Pricing**: In a competitive market, companies may adopt competitive pricing strategies to attract customers and gain market share.

B. Marketing and Distribution Channels

Effective marketing and distribution channels are essential for reaching target customers:

1. **Direct Sales vs. Distributors**: Companies must decide whether to sell directly to customers or through distributors, each having its advantages and challenges.

2. **Online Marketplaces**: The rise of e-commerce has opened new avenues for selling aluminum electrolytic capacitors, allowing manufacturers to reach a broader audience.

C. Innovation and R&D Investments

Investing in research and development (R&D) is critical for staying competitive in the aluminum electrolytic capacitor market:

1. **Technological Advancements**: Companies are continually seeking to improve capacitor performance, reliability, and efficiency through technological innovations.

2. **Product Development Trends**: The industry is witnessing trends toward smaller, more efficient capacitors that meet the demands of modern electronic devices.

VII. Challenges and Opportunities

A. Market Challenges

The aluminum electrolytic capacitor market faces several challenges:

1. **Supply Chain Disruptions**: Global events, such as pandemics or geopolitical tensions, can disrupt supply chains, leading to delays and increased costs.

2. **Competition from Alternative Technologies**: Emerging technologies, such as solid-state capacitors, pose a competitive threat to traditional aluminum electrolytic capacitors, requiring manufacturers to innovate continuously.

B. Opportunities for Growth

Despite challenges, there are significant opportunities for growth in the aluminum electrolytic capacitor market:

1. **Emerging Markets**: Rapid industrialization and urbanization in emerging markets present opportunities for increased demand for electronic components, including capacitors.

2. **Advancements in Technology**: Ongoing advancements in technology create opportunities for manufacturers to develop new products that meet evolving consumer needs.

VIII. Conclusion

In conclusion, the market policies surrounding aluminum electrolytic capacitors are shaped by a complex interplay of regulatory frameworks, trade policies, environmental considerations, and market strategies. As the demand for these essential components continues to grow, manufacturers must navigate these policies effectively to remain competitive. By embracing sustainability initiatives, investing in innovation, and adapting to changing market dynamics, companies can position themselves for success in the evolving landscape of aluminum electrolytic capacitors.

IX. References

1. Academic Journals

2. Industry Reports

3. Regulatory Bodies and Standards Organizations

This blog post provides a comprehensive overview of the market policies for aluminum electrolytic capacitors, highlighting the importance of understanding these policies for manufacturers and stakeholders in the industry.