What Kind of Product Are Power Wirewound Resistors?

I. Introduction

Power wirewound resistors are essential components in the world of electronics and electrical engineering. These resistors are designed to handle significant amounts of power while providing precise resistance values, making them indispensable in various applications. In this article, we will explore what power wirewound resistors are, their characteristics, applications, advantages, limitations, and future trends in resistor technology.

II. Understanding Resistors

A. Basic Function of Resistors

Resistors are passive electrical components that limit the flow of electric current in a circuit. They serve two primary functions:

1. **Current Limiting**: Resistors restrict the amount of current that can flow through a circuit, protecting sensitive components from damage due to excessive current.

2. **Voltage Division**: Resistors can divide voltage in a circuit, allowing for the creation of different voltage levels necessary for various components.

B. Types of Resistors

Resistors come in various types, each serving specific purposes:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in circuits where precise resistance is required.

2. **Variable Resistors**: Also known as potentiometers, these resistors allow users to adjust the resistance value, making them suitable for applications like volume controls.

3. **Specialty Resistors**: This category includes various resistors designed for specific applications, such as thermistors and photoresistors.

III. What Are Wirewound Resistors?

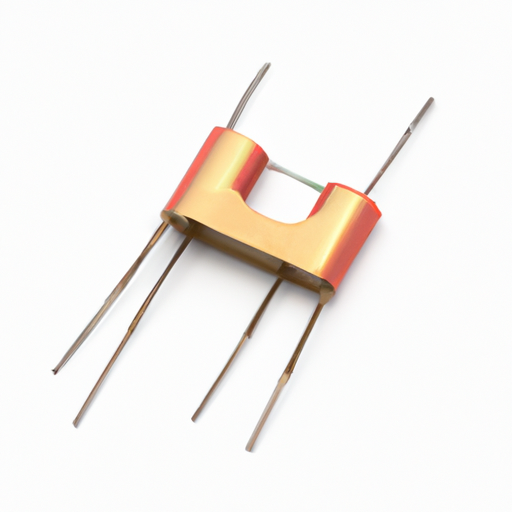

A. Construction and Materials

Wirewound resistors are a type of fixed resistor constructed by winding a metal wire around a core. The materials used in their construction significantly influence their performance:

1. **Wire Material**: Common wire materials include nickel-chromium and copper-nickel alloys, chosen for their stability and resistance to oxidation.

2. **Core Material**: The core is typically made from ceramic or other insulating materials, providing structural integrity and thermal stability.

B. Manufacturing Process

The manufacturing process of wirewound resistors involves several steps:

1. **Winding Techniques**: The wire is wound around the core in a precise manner to achieve the desired resistance value. The number of turns and the wire's thickness determine the final resistance.

2. **Resistance Value Calibration**: After winding, the resistors undergo calibration to ensure they meet specified resistance values and tolerances.

IV. Characteristics of Power Wirewound Resistors

A. Power Rating

The power rating of a resistor indicates the maximum amount of power it can dissipate without overheating. This characteristic is crucial for applications where high power levels are involved. Power wirewound resistors typically have higher power ratings compared to other resistor types, making them suitable for demanding applications.

B. Tolerance and Temperature Coefficient

1. **Importance of Tolerance**: Tolerance refers to the allowable deviation from the specified resistance value. In applications where precision is critical, low-tolerance resistors are preferred.

2. **Temperature Coefficient**: This parameter indicates how much the resistance value changes with temperature. A low temperature coefficient is desirable for maintaining performance across varying environmental conditions.

C. Inductance and Frequency Response

1. **Inductance in Wirewound Resistors**: Due to their construction, wirewound resistors can exhibit inductance, which may affect their performance in high-frequency applications.

2. **Frequency Response Characteristics**: Understanding the frequency response of wirewound resistors is essential for applications involving alternating current (AC) signals, as it can impact signal integrity.

V. Applications of Power Wirewound Resistors

A. Power Electronics

Power wirewound resistors are widely used in power electronics, including:

1. **Use in Power Supplies**: They help regulate voltage and current in power supply circuits, ensuring stable operation.

2. **Role in Motor Control Circuits**: These resistors are crucial in controlling the speed and torque of electric motors.

B. Audio Equipment

In audio applications, power wirewound resistors play a vital role:

1. **Use in Amplifiers**: They are used in audio amplifiers to manage power levels and improve sound quality.

2. **Impact on Sound Quality**: The precision and stability of wirewound resistors contribute to the overall performance of audio systems.

C. Industrial Applications

Power wirewound resistors find applications in various industrial settings:

1. **Load Testing**: They are used in load testing equipment to simulate different load conditions.

2. **Heating Elements**: Their ability to handle high power makes them suitable for use as heating elements in industrial processes.

D. Automotive Applications

In the automotive industry, power wirewound resistors are increasingly important:

1. **Use in Electric Vehicles**: They are used in electric vehicle systems for power management and control.

2. **Role in Battery Management Systems**: These resistors help regulate battery charging and discharging, ensuring optimal performance and longevity.

VI. Advantages of Power Wirewound Resistors

Power wirewound resistors offer several advantages:

A. High Power Handling Capability

Their design allows them to handle significant power levels, making them suitable for high-demand applications.

B. Stability and Reliability

Wirewound resistors are known for their stability over time, ensuring consistent performance in various conditions.

C. Precision and Accuracy

With low tolerance levels, power wirewound resistors provide precise resistance values, essential for critical applications.

D. Wide Range of Resistance Values

They are available in a broad range of resistance values, making them versatile for different applications.

VII. Limitations of Power Wirewound Resistors

Despite their advantages, power wirewound resistors have some limitations:

A. Size and Weight Considerations

Power wirewound resistors tend to be larger and heavier than other resistor types, which can be a drawback in compact electronic designs.

B. Inductance Issues in High-Frequency Applications

The inductance associated with wirewound resistors can lead to performance issues in high-frequency applications, necessitating careful selection.

C. Cost Factors Compared to Other Resistor Types

Power wirewound resistors can be more expensive than other resistor types, which may be a consideration for budget-sensitive projects.

VIII. Conclusion

In summary, power wirewound resistors are crucial components in modern electronics, offering high power handling, precision, and reliability. Their applications span various industries, from power electronics to automotive systems. As technology advances, we can expect to see further innovations in resistor technology, enhancing performance and expanding their applications. Understanding the significance of power wirewound resistors is essential for anyone involved in electrical engineering and electronics, as they play a vital role in ensuring the functionality and efficiency of electronic devices.

IX. References

A. Suggested Reading

- "Resistor Technology: A Comprehensive Guide" by John Doe

- "Understanding Resistors: Theory and Applications" by Jane Smith

B. Industry Standards and Guidelines

- IEC 60115: Resistors for use in electronic equipment

- EIA-198: Standard for Fixed Resistors

C. Manufacturer Resources

- Vishay Intertechnology: Resistor Product Catalog

- Ohmite Manufacturing: Wirewound Resistor Technical Data

This blog post provides a detailed overview of power wirewound resistors, highlighting their importance in various applications and their unique characteristics. Understanding these components is essential for anyone working in the field of electronics and electrical engineering.