Common Power Inductor Popular Models

I. Introduction

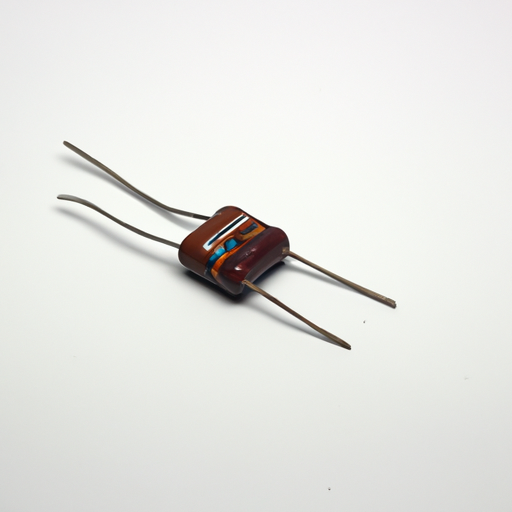

A. Definition of Power Inductors

Power inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They are essential in various electronic circuits, particularly in power management applications, where they help regulate voltage and current levels.

B. Importance of Power Inductors in Electronic Circuits

In the realm of electronics, power inductors play a crucial role in filtering, energy storage, and voltage regulation. They are commonly found in power supply circuits, DC-DC converters, and other applications where stable power delivery is essential. Their ability to manage energy efficiently makes them indispensable in modern electronic devices.

C. Overview of the Article's Purpose

This article aims to provide an in-depth understanding of power inductors, explore popular models available in the market, and discuss their applications and selection criteria. By the end, readers will have a comprehensive overview of power inductors and their significance in electronic design.

II. Understanding Power Inductors

A. Basic Principles of Inductance

1. Definition of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. It is measured in henries (H) and is defined as the ratio of the induced voltage to the rate of change of current.

2. How Inductors Work

When current flows through an inductor, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage that opposes the change in current. This property is known as self-inductance and is fundamental to the operation of inductors in circuits.

B. Types of Power Inductors

1. Air Core Inductors

Air core inductors use air as the core material. They are typically used in high-frequency applications due to their low losses but are less efficient in power applications compared to other types.

2. Iron Core Inductors

Iron core inductors use iron as the core material, which increases the inductance and allows for higher current ratings. However, they can suffer from core losses at high frequencies.

3. Ferrite Core Inductors

Ferrite core inductors use ferrite materials, which provide high magnetic permeability and low losses at high frequencies. They are widely used in power applications due to their efficiency and compact size.

C. Key Specifications

1. Inductance Value

The inductance value, measured in henries, indicates the inductor's ability to store energy. It is a critical specification that determines the inductor's performance in a circuit.

2. Current Rating

The current rating specifies the maximum current the inductor can handle without overheating or saturating. Exceeding this rating can lead to failure or reduced performance.

3. DC Resistance (DCR)

DC resistance is the resistance of the inductor when a direct current flows through it. Lower DCR values are preferred as they result in less power loss and heat generation.

4. Saturation Current

Saturation current is the maximum current the inductor can handle before the core material becomes saturated, leading to a significant drop in inductance. It is crucial to select an inductor with a saturation current rating that exceeds the application's requirements.

III. Popular Models of Power Inductors

A. Overview of Market Leaders

Several manufacturers dominate the power inductor market, known for their quality and reliability. Key players include:

1. **Coilcraft**

2. **Vishay**

3. **Murata**

4. **TDK**

5. **Wurth Elektronik**

B. Detailed Analysis of Selected Models

1. Coilcraft LPS Series

Specifications: The LPS series offers inductance values ranging from 1.0 µH to 1000 µH, with current ratings up to 30 A and low DCR values.

Applications: Ideal for DC-DC converters, power supplies, and energy storage applications.

2. Vishay IHLP Series

Specifications: The IHLP series features inductance values from 1.0 µH to 1000 µH, with high saturation current ratings and low DCR.

Applications: Commonly used in automotive, industrial, and telecommunications applications.

3. Murata LQH Series

Specifications: The LQH series provides a wide range of inductance values, with compact sizes and high current ratings.

Applications: Suitable for power management in consumer electronics and portable devices.

4. TDK RDK Series

Specifications: The RDK series offers high inductance values with excellent thermal performance and low DCR.

Applications: Used in power supply circuits and DC-DC converters.

5. Wurth Elektronik WE-PD Series

Specifications: The WE-PD series features low-profile designs with high current ratings and low DCR.

Applications: Ideal for applications requiring compact size and high efficiency, such as in mobile devices.

IV. Applications of Power Inductors

A. Power Supply Circuits

Power inductors are essential in power supply circuits, where they help regulate voltage and current levels, ensuring stable operation of electronic devices.

B. DC-DC Converters

In DC-DC converters, inductors store energy and release it as needed, allowing for efficient voltage conversion and regulation.

C. RF Applications

Power inductors are used in RF applications to filter signals and manage power levels, ensuring optimal performance in communication devices.

D. Automotive Electronics

In automotive applications, power inductors are crucial for managing power in various systems, including engine control units and infotainment systems.

E. Consumer Electronics

From smartphones to laptops, power inductors are integral to the performance and efficiency of consumer electronics, enabling compact designs and reliable operation.

V. Factors to Consider When Choosing a Power Inductor

A. Application Requirements

Understanding the specific requirements of the application, such as voltage, current, and frequency, is essential for selecting the right inductor.

B. Size and Form Factor

The physical size and form factor of the inductor can impact the overall design of the circuit. Smaller inductors are often preferred for compact devices.

C. Thermal Management

Consideration of thermal performance is crucial, as inductors can generate heat during operation. Proper thermal management ensures reliability and longevity.

D. Cost Considerations

While performance is critical, cost is also a significant factor. Balancing performance with budget constraints is essential for successful design.

VI. Future Trends in Power Inductor Technology

A. Miniaturization and High Efficiency

As electronic devices continue to shrink, the demand for smaller, more efficient inductors is increasing. Manufacturers are focusing on developing compact designs without compromising performance.

B. Integration with Other Components

Future trends may see power inductors integrated with other components, such as capacitors and resistors, to create more compact and efficient power management solutions.

C. Advances in Materials and Manufacturing Techniques

Innovations in materials and manufacturing processes are leading to the development of inductors with improved performance characteristics, such as higher saturation current and lower losses.

VII. Conclusion

A. Recap of the Importance of Power Inductors

Power inductors are vital components in modern electronic circuits, playing a crucial role in energy management and regulation.

B. Summary of Popular Models and Their Applications

The article has explored several popular power inductor models, highlighting their specifications and applications across various industries.

C. Final Thoughts on Selecting the Right Power Inductor for Specific Needs

Choosing the right power inductor involves understanding the specific requirements of the application, considering factors such as size, thermal performance, and cost. By carefully evaluating these aspects, designers can select the most suitable inductor for their needs.

VIII. References

A. List of Sources for Further Reading

1. Manufacturer datasheets and technical documents

2. Industry publications and journals on power electronics

B. Manufacturer Websites and Technical Datasheets

- Coilcraft: [www.coilcraft.com](http://www.coilcraft.com)

- Vishay: [www.vishay.com](http://www.vishay.com)

- Murata: [www.murata.com](http://www.murata.com)

- TDK: [www.tdk.com](http://www.tdk.com)

- Wurth Elektronik: [www.wurth-elektronik.com](http://www.wurth-elektronik.com)

This comprehensive overview of power inductors and their popular models provides valuable insights for engineers and designers looking to optimize their electronic circuits.