Precautions for Capacitor Housing Product Training

I. Introduction

In the world of electronics, capacitors play a crucial role in the functionality of devices ranging from simple household appliances to complex industrial machinery. The housing of these capacitors is equally important, as it protects the internal components and ensures safe operation. This blog post aims to provide a comprehensive overview of the precautions necessary for effective training on capacitor housing products. By emphasizing safety and best practices, we can foster a culture of awareness and responsibility among trainees, ultimately contributing to a safer working environment.

II. Understanding Capacitor Housing

A. Definition and Function of Capacitor Housing

Capacitor housing refers to the protective casing that encases the capacitor's internal components. This housing serves multiple functions, including safeguarding the capacitor from physical damage, preventing electrical shorts, and ensuring that the capacitor operates within its specified parameters. The design and material of the housing can significantly influence the capacitor's performance and longevity.

B. Types of Capacitor Housings

1. **Plastic Housings**: These are lightweight and resistant to corrosion, making them suitable for a variety of applications. Plastic housings are often used in consumer electronics due to their cost-effectiveness and ease of manufacturing.

2. **Metal Housings**: Metal housings provide superior protection against physical damage and electromagnetic interference. They are commonly used in industrial applications where durability is paramount.

3. **Hybrid Housings**: Combining the benefits of both plastic and metal, hybrid housings offer a balance of lightweight design and robust protection. These are often used in specialized applications where both weight and durability are critical.

C. Common Applications of Capacitors in Various Industries

Capacitors are ubiquitous in modern electronics. They are used in power supplies, audio equipment, automotive systems, and telecommunications, among others. Understanding the various applications helps trainees appreciate the importance of proper handling and training related to capacitor housings.

III. Safety Precautions Before Training

A. Personal Protective Equipment (PPE)

Safety begins with the right personal protective equipment. Trainees should be equipped with:

1. **Gloves**: To protect hands from sharp edges and potential chemical exposure.

2. **Safety Goggles**: To shield eyes from debris and potential chemical splashes.

3. **ESD (Electrostatic Discharge) Wrist Straps**: To prevent damage to sensitive electronic components by discharging static electricity safely.

B. Environmental Considerations

Creating a safe training environment is essential. Key considerations include:

1. **Proper Ventilation**: Ensuring adequate airflow to prevent the buildup of harmful fumes, especially when working with materials that may emit volatile compounds.

2. **Clean Workspace**: A clutter-free area reduces the risk of accidents and makes it easier to locate tools and materials.

3. **Fire Safety Measures**: Having fire extinguishers and first aid kits readily available can mitigate risks associated with electrical fires or chemical spills.

IV. Handling Capacitor Housings

A. Proper Lifting Techniques

When handling capacitor housings, trainees should be trained in proper lifting techniques to avoid injury. This includes bending at the knees, keeping the load close to the body, and avoiding twisting motions.

B. Avoiding Physical Damage

Capacitor housings can be fragile, especially plastic ones. Trainees should be instructed to handle them with care, avoiding dropping or striking them against hard surfaces.

C. Understanding the Risks of Electrical Shock

Capacitors can hold a charge even after being disconnected from a power source. Trainees must be educated on the risks of electrical shock and the importance of discharging capacitors safely before handling them.

D. Guidelines for Transporting Capacitors

When transporting capacitors, it is crucial to secure them properly to prevent movement and potential damage. Using padded containers or boxes can help protect the housings during transit.

V. Training Procedures

A. Overview of Training Modules

The training should be structured into modules that cover both theoretical knowledge and hands-on practice. This dual approach ensures that trainees not only understand the concepts but also gain practical experience.

1. **Theoretical Knowledge**: This module should cover the types of capacitor housings, their functions, and safety precautions.

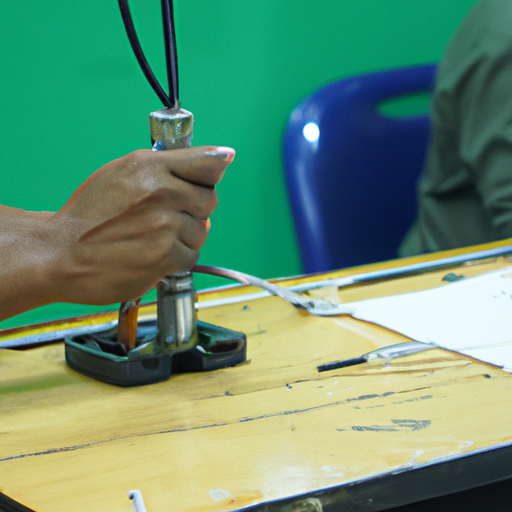

2. **Hands-on Practice**: Trainees should engage in practical exercises that involve handling, discharging, and assembling capacitors.

B. Importance of Following the Training Schedule

Adhering to the training schedule is vital for ensuring that all topics are covered comprehensively. It also helps maintain a structured learning environment.

C. Role of Trainers and Trainees in Ensuring Safety

Trainers should lead by example, demonstrating safe practices and encouraging trainees to ask questions. Trainees, in turn, should actively participate and communicate any concerns regarding safety.

VI. Common Hazards and How to Mitigate Them

A. Electrical Hazards

1. **Identifying Charged Capacitors**: Trainees should learn to recognize indicators of charged capacitors and understand the importance of using appropriate tools to check for voltage.

2. **Discharge Procedures**: Proper procedures for discharging capacitors should be emphasized, including the use of resistors and insulated tools.

B. Chemical Hazards

1. **Understanding Materials Used in Housings**: Trainees should be educated about the materials used in capacitor housings and any associated risks, such as toxicity or flammability.

2. **Safe Handling of Hazardous Substances**: Proper protocols for handling and disposing of hazardous materials should be established.

C. Mechanical Hazards

1. **Risks Associated with Tools and Equipment**: Trainees should be trained on the safe use of tools and equipment, including the importance of using the right tool for the job.

2. **Safe Operation of Machinery**: If machinery is involved in the training, proper operating procedures should be outlined to prevent accidents.

VII. Emergency Procedures

A. First Aid for Electrical Shock

In the event of an electrical shock, trainees should know the immediate steps to take, including calling for medical assistance and performing CPR if necessary.

B. Responding to Chemical Spills

Trainees should be familiar with the procedures for responding to chemical spills, including evacuation protocols and the use of spill kits.

C. Reporting Incidents and Near Misses

Encouraging a culture of reporting incidents and near misses can help identify potential hazards and improve safety practices.

VIII. Post-Training Evaluation

A. Importance of Feedback

Feedback from trainees is essential for assessing the effectiveness of the training program. It can provide insights into areas that may need improvement.

B. Assessing Knowledge Retention

Quizzes or practical assessments can help evaluate trainees' understanding of the material covered during training.

C. Continuous Improvement in Safety Practices

Regularly reviewing and updating training materials and safety protocols can help ensure that safety practices remain relevant and effective.

IX. Conclusion

In conclusion, the importance of precautions in capacitor housing training cannot be overstated. By prioritizing safety and best practices, we can create a culture of awareness that benefits both trainees and the broader electronics industry. Ongoing education and safety awareness are essential for minimizing risks and ensuring the safe handling of capacitor housings. As we move forward, let us remain committed to fostering a safe and responsible working environment.

X. References

A. Suggested readings and resources for further exploration of capacitor technology and safety practices.

B. Industry standards and guidelines that govern the safe handling of electronic components.

C. Contact information for further inquiries and support related to capacitor housing training.

By following these guidelines and emphasizing safety, we can ensure that our training programs are effective and contribute to a safer workplace for all involved.