What are the Advantages of Standard Capacitor Products?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to filtering signals in audio equipment. As technology advances, the demand for reliable and efficient capacitors has led to the development of standard capacitor products. These products are manufactured to meet specific industry standards, ensuring consistency and reliability across various applications. In this blog post, we will explore the advantages of standard capacitor products, their types, applications, and the challenges associated with their use.

II. Types of Standard Capacitors

Standard capacitors come in various types, each designed for specific applications and performance characteristics. Here are some of the most common types:

A. Ceramic Capacitors

Ceramic capacitors are widely used due to their small size, low cost, and excellent frequency characteristics. They are ideal for high-frequency applications and are often found in RF circuits and decoupling applications.

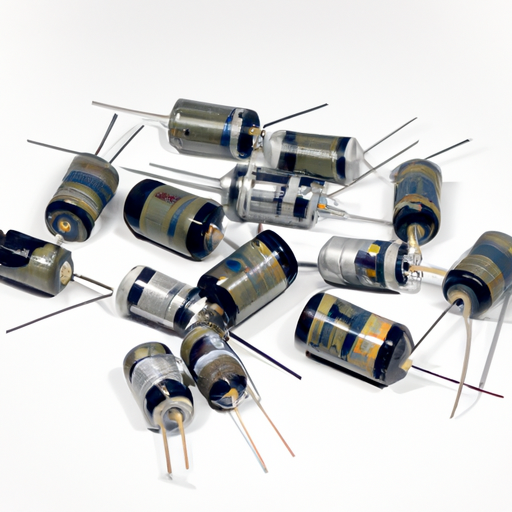

B. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values and are commonly used in power supply circuits. They are polarized, meaning they have a positive and negative terminal, which must be connected correctly to avoid damage.

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their stability and low loss characteristics. They are often used in audio applications and power electronics due to their reliability and performance.

D. Tantalum Capacitors

Tantalum capacitors offer high capacitance in a small package and are known for their reliability. They are often used in applications where space is limited, such as in mobile devices and compact electronic circuits.

E. Supercapacitors

Supercapacitors, or ultracapacitors, are designed for high energy storage and rapid charge/discharge cycles. They are increasingly used in renewable energy systems and electric vehicles due to their ability to store large amounts of energy.

III. Advantages of Standard Capacitor Products

Standard capacitor products offer numerous advantages that make them a preferred choice for many applications. Here are some of the key benefits:

A. Consistency and Reliability

1. **Manufacturing Standards**: Standard capacitors are produced according to strict manufacturing standards, ensuring that each component meets specific performance criteria. This consistency is crucial for applications where reliability is paramount.

2. **Quality Control Measures**: Manufacturers implement rigorous quality control measures throughout the production process. This includes testing for capacitance, voltage ratings, and other performance metrics, ensuring that only high-quality products reach the market.

3. **Long-term Performance Stability**: Standard capacitors are designed for long-term stability, which is essential for applications that require consistent performance over time. This reliability reduces the risk of failure and enhances the overall performance of electronic devices.

B. Cost-Effectiveness

1. **Economies of Scale in Production**: Standard capacitors are produced in large quantities, allowing manufacturers to benefit from economies of scale. This results in lower production costs, which can be passed on to consumers.

2. **Competitive Pricing**: The widespread availability of standard capacitors leads to competitive pricing in the market. This makes them an attractive option for manufacturers looking to keep costs down while maintaining quality.

3. **Reduced Need for Custom Solutions**: By using standard capacitors, manufacturers can avoid the costs and complexities associated with custom capacitor solutions. This streamlines the design process and reduces lead times.

C. Availability and Accessibility

1. **Wide Range of Options**: Standard capacitors come in various types, sizes, and ratings, providing designers with a wide range of options to choose from. This flexibility allows for easy integration into different applications.

2. **Global Distribution Networks**: Standard capacitors are widely available through global distribution networks, making it easy for manufacturers to source the components they need, regardless of their location.

3. **Quick Turnaround Times for Orders**: The availability of standard capacitors means that manufacturers can often receive their orders quickly, reducing downtime and allowing for faster product development cycles.

D. Compatibility and Interchangeability

1. **Standardized Sizes and Ratings**: Standard capacitors are manufactured to specific sizes and ratings, making them compatible with a wide range of electronic designs. This standardization simplifies the design process and reduces the risk of errors.

2. **Ease of Integration into Existing Designs**: Designers can easily integrate standard capacitors into existing circuits without the need for extensive modifications. This compatibility is particularly beneficial for retrofitting older designs.

3. **Simplified Replacement Processes**: When a capacitor fails, using a standard product makes it easier to find a suitable replacement. This reduces maintenance time and costs, ensuring that devices remain operational.

E. Enhanced Performance Characteristics

1. **Improved Capacitance Stability**: Standard capacitors are designed to provide stable capacitance over a wide range of operating conditions. This stability is crucial for applications that require precise performance.

2. **Lower Equivalent Series Resistance (ESR)**: Many standard capacitors are designed with low ESR, which improves their efficiency and performance in high-frequency applications. This characteristic is particularly important in power supply circuits.

3. **Higher Voltage Ratings and Temperature Tolerances**: Standard capacitors are available with a range of voltage ratings and temperature tolerances, allowing them to be used in various environments and applications.

F. Regulatory Compliance and Certification

1. **Adherence to International Standards**: Standard capacitors are manufactured in compliance with international standards, ensuring that they meet specific performance and safety criteria. This compliance is essential for manufacturers looking to sell their products globally.

2. **Safety Certifications**: Many standard capacitors come with safety certifications, providing assurance to manufacturers and consumers that the products are safe to use in their intended applications.

3. **Environmental Considerations**: Manufacturers of standard capacitors often adhere to environmental regulations, ensuring that their products are produced sustainably and with minimal impact on the environment.

IV. Applications of Standard Capacitor Products

Standard capacitors are used in a wide range of applications across various industries. Here are some key areas where they play a vital role:

A. Consumer Electronics

In consumer electronics, standard capacitors are used in devices such as smartphones, tablets, and televisions. They help stabilize power supplies, filter signals, and improve overall performance.

B. Automotive Industry

The automotive industry relies on standard capacitors for various applications, including power management systems, audio systems, and safety features. Their reliability and performance are critical for ensuring the safety and functionality of modern vehicles.

C. Industrial Machinery

Standard capacitors are used in industrial machinery for power factor correction, motor starting, and energy storage. Their ability to handle high voltages and currents makes them suitable for demanding industrial applications.

D. Telecommunications

In telecommunications, standard capacitors are essential for signal processing, filtering, and power supply stabilization. They help ensure reliable communication in various devices, from cell towers to networking equipment.

E. Renewable Energy Systems

As the demand for renewable energy sources grows, standard capacitors are increasingly used in solar inverters, wind turbines, and energy storage systems. Their ability to store and release energy efficiently is crucial for the success of these technologies.

V. Challenges and Considerations

While standard capacitors offer numerous advantages, there are also challenges and considerations to keep in mind:

A. Limitations of Standard Capacitors

Standard capacitors may not always meet the specific requirements of certain applications. In cases where unique performance characteristics are needed, custom capacitors may be necessary.

B. Situations Where Custom Capacitors May Be Necessary

Certain applications, such as high-frequency RF circuits or specialized medical devices, may require custom capacitors designed to meet specific performance criteria. In these cases, manufacturers must weigh the benefits of standard products against the need for custom solutions.

C. Importance of Selecting the Right Capacitor for Specific Applications

Choosing the right capacitor for a specific application is crucial for ensuring optimal performance. Designers must consider factors such as capacitance, voltage rating, temperature tolerance, and size when selecting a capacitor.

VI. Conclusion

In summary, standard capacitor products offer numerous advantages, including consistency, cost-effectiveness, availability, compatibility, enhanced performance, and regulatory compliance. These benefits make them a preferred choice for a wide range of applications across various industries. As technology continues to evolve, the role of standard capacitors in modern electronics will only become more significant. Manufacturers and designers must stay informed about the latest trends in capacitor technology to ensure they are making the best choices for their applications.

VII. References

1. Academic journals on capacitor technology and applications.

2. Industry reports on the capacitor market and trends.

3. Manufacturer specifications and datasheets for various types of standard capacitors.

By understanding the advantages and applications of standard capacitor products, manufacturers can make informed decisions that enhance the performance and reliability of their electronic devices.