The Latest Capacitor Protection Specifications

I. Introduction

Capacitors are essential components in electrical systems, serving various functions such as energy storage, filtering, and voltage regulation. However, their effectiveness can be compromised without proper protection. Capacitor protection refers to the measures and specifications designed to safeguard capacitors from potential risks that could lead to failure. This blog post aims to explore the latest capacitor protection specifications, emphasizing their importance in maintaining the reliability and safety of electrical systems.

II. Understanding Capacitors

A. Basic Functionality of Capacitors

Capacitors store electrical energy in an electric field, allowing them to release this energy when needed. They are characterized by their capacitance, which is the ability to store charge, and are widely used in various applications, from power supply circuits to signal processing.

B. Types of Capacitors

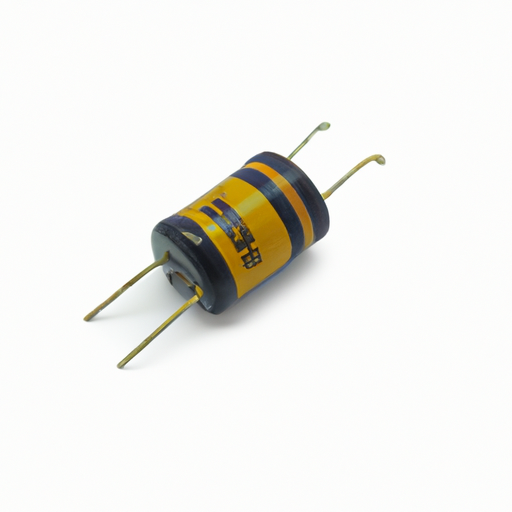

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and often used in power supply applications.

2. **Ceramic Capacitors**: These non-polarized capacitors are commonly used in high-frequency applications due to their stability and low losses.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their reliability and are often used in audio and power applications.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package and are used in applications where space is limited.

C. Common Applications of Capacitors

Capacitors are utilized in various sectors, including consumer electronics, automotive systems, renewable energy systems, and industrial machinery. Their versatility makes them indispensable in modern electrical engineering.

III. The Need for Capacitor Protection

A. Risks Associated with Unprotected Capacitors

Capacitors face several risks that can lead to failure if not adequately protected:

1. **Overvoltage**: Excess voltage can cause dielectric breakdown, leading to catastrophic failure.

2. **Overcurrent**: High current can generate excessive heat, damaging the capacitor and surrounding components.

3. **Temperature Extremes**: Capacitors are sensitive to temperature fluctuations, which can affect their performance and lifespan.

B. Consequences of Capacitor Failure

The failure of a capacitor can have severe consequences, including:

1. **Equipment Damage**: A failed capacitor can lead to circuit malfunctions, damaging other components.

2. **Safety Hazards**: Exploding or leaking capacitors can pose safety risks to personnel and equipment.

3. **Downtime and Economic Impact**: Equipment failures can result in costly downtime and repairs, affecting productivity and profitability.

IV. Overview of Capacitor Protection Specifications

A. Industry Standards and Guidelines

Several organizations establish standards and guidelines for capacitor protection:

1. **IEC (International Electrotechnical Commission)**: Provides international standards for electrical and electronic devices, including capacitors.

2. **UL (Underwriters Laboratories)**: Focuses on safety standards for electrical devices, ensuring that capacitors meet safety requirements.

3. **IEEE (Institute of Electrical and Electronics Engineers)**: Develops standards for electrical and electronic systems, including specifications for capacitors.

B. Key Specifications to Consider

When selecting capacitors and their protection mechanisms, several key specifications should be considered:

1. **Voltage Ratings**: Ensure that capacitors can handle the maximum voltage they will encounter in operation.

2. **Current Ratings**: Capacitors should be rated for the expected current to prevent overheating and failure.

3. **Temperature Ratings**: Select capacitors that can operate within the temperature range of the application.

4. **Surge Protection**: Implement surge protection devices to safeguard against voltage spikes.

5. **Lifetime and Reliability Metrics**: Consider the expected lifespan and reliability of capacitors in the intended application.

V. Latest Developments in Capacitor Protection Technologies

A. Advanced Materials and Designs

Recent advancements in capacitor technology have led to the development of new materials and designs that enhance protection:

1. **Nanotechnology in Capacitor Manufacturing**: The use of nanomaterials can improve the performance and reliability of capacitors, making them more resistant to failure.

2. **Self-healing Capacitors**: These innovative capacitors can repair themselves after damage, significantly extending their lifespan.

B. Smart Capacitor Protection Systems

The integration of smart technologies into capacitor protection systems is revolutionizing the industry:

1. **Monitoring and Diagnostics**: Advanced monitoring systems can provide real-time data on capacitor performance, allowing for proactive maintenance.

2. **Integration with IoT (Internet of Things)**: IoT-enabled capacitors can communicate with other devices, enhancing system efficiency and reliability.

C. Enhanced Safety Features

Modern capacitors are equipped with enhanced safety features to mitigate risks:

1. **Fuses and Circuit Breakers**: These devices can disconnect the capacitor from the circuit in case of overcurrent or short circuits.

2. **Thermal Protection Mechanisms**: Temperature sensors can trigger shutdowns or alerts when capacitors exceed safe operating temperatures.

VI. Best Practices for Implementing Capacitor Protection

A. Selection Criteria for Capacitor Protection Devices

When selecting protection devices, consider factors such as compatibility with the capacitor type, voltage and current ratings, and environmental conditions.

B. Installation Guidelines

Proper installation is crucial for effective capacitor protection. Follow manufacturer guidelines and industry standards to ensure safe and reliable operation.

C. Regular Maintenance and Testing

Routine maintenance and testing of capacitors and their protection systems can identify potential issues before they lead to failure. Implement a regular inspection schedule to ensure optimal performance.

D. Training and Awareness for Personnel

Educating personnel about capacitor protection and safety measures is essential. Training programs can help staff recognize potential risks and respond appropriately.

VII. Case Studies

A. Successful Implementation of Capacitor Protection in Industry

Several industries have successfully implemented capacitor protection measures, resulting in improved reliability and safety. For example, a manufacturing facility that upgraded its capacitor protection systems reported a significant reduction in equipment failures and downtime.

B. Lessons Learned from Capacitor Failures

Analyzing past capacitor failures can provide valuable insights into the importance of proper protection. For instance, a case study of a power plant that experienced a catastrophic capacitor failure highlighted the need for stringent voltage and temperature monitoring.

C. Innovations Driven by Real-World Challenges

Real-world challenges have driven innovations in capacitor protection technologies. For example, the demand for more compact and efficient capacitors has led to the development of advanced materials and designs that enhance performance and safety.

VIII. Future Trends in Capacitor Protection

A. Emerging Technologies

The future of capacitor protection will likely see the emergence of new technologies, such as advanced materials and smart monitoring systems, that enhance reliability and safety.

B. Regulatory Changes and Their Impact

As technology evolves, regulatory bodies may update standards and guidelines for capacitor protection, impacting design and manufacturing practices.

C. Predictions for the Next Decade

In the next decade, the capacitor protection landscape is expected to evolve significantly, with increased emphasis on sustainability, efficiency, and integration with smart technologies.

IX. Conclusion

Capacitor protection is a critical aspect of electrical systems, ensuring the reliability and safety of these essential components. As technology advances, staying informed about the latest specifications and best practices is vital for industry stakeholders. By prioritizing capacitor protection, organizations can mitigate risks, enhance performance, and contribute to a safer and more efficient electrical infrastructure.

X. References

A comprehensive list of relevant standards, academic publications, and additional resources can provide further insights into capacitor protection specifications and best practices. For those interested in delving deeper, exploring these references will enhance understanding and implementation of effective capacitor protection measures.